TECH INFO

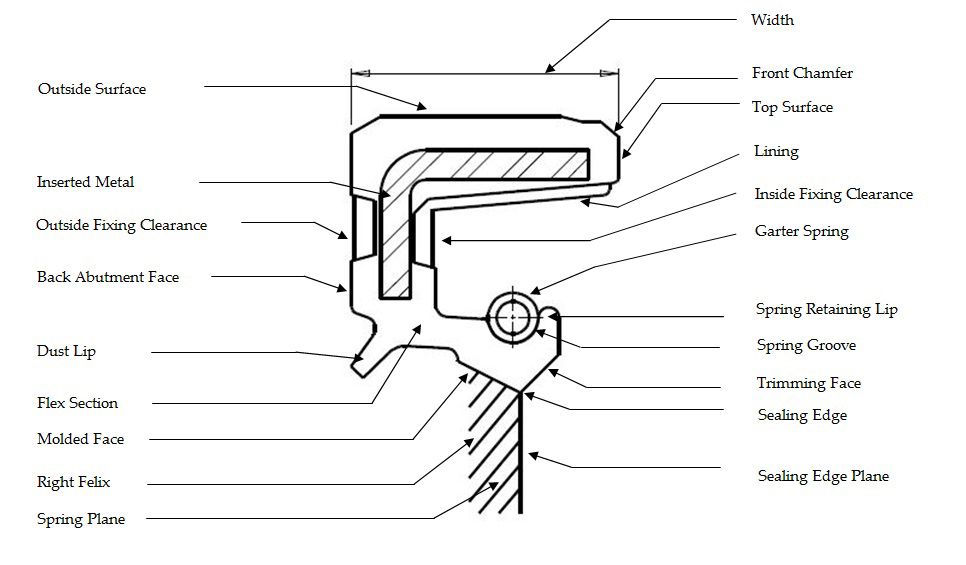

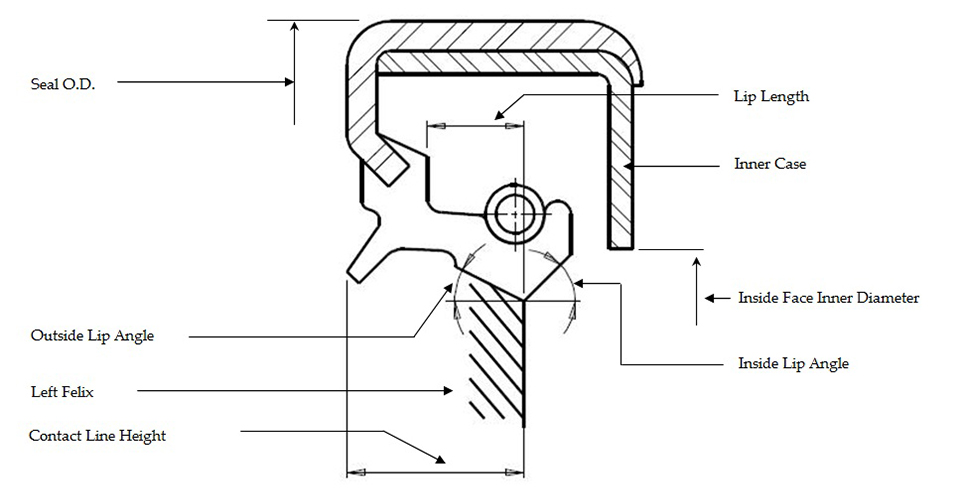

Oil Seal Glossary

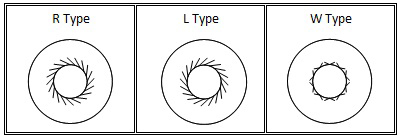

Helix

Oil Seal Tolerance

TABLE 1. SHAFT TOLERANCE (IMPERIAL)

| NOMINAL SHAFT DIAMETER | TOLERANCE | ||

|---|---|---|---|

| up to 4.000 | ± 0.003 | ||

| over 4.000 to 6.000 | ± 0.004 | ||

| over 6.000 to 10.000 | ± 0.005 | ||

| over 10.000 | ± 0.006 | ||

TABLE 2. SHAFT TOLERANCE (METRIC)

| SHAFT DIA. | TOLERANCE in μm | ||

|---|---|---|---|

| over | to | Lower | upper |

| 0 | 3 | 0 | -60 |

| 3 | 6 | 0 | -75 |

| 6 | 10 | 0 | -90 |

| 10 | 18 | 0 | -110 |

| 18 | 30 | 0 | -130 |

| 30 | 50 | 0 | -160 |

| 50 | 80 | 0 | -190 |

| 80 | 120 | 0 | -220 |

| 120 | 180 | 0 | -250 |

| 180 | 250 | 0 | -290 |

| 250 | 315 | 0 | -320 |

| 315 | 400 | 0 | -360 |

| 400 | 500 | 0 | -400 |

TABLE 3. HOUSING TOLERANCE (IMPERIAL)

| BORE DIA. (inch) | BORE TOLERANCE |

|---|---|

| up to 3.000 | ± 0.0010 |

| 3.001 to 6.000 | ± 0.0015 |

| 6.001 to 10.000 | ± 0.0020 |

| 10.001 to 20.000 | + 0.002 / -0.004 |

| 20.001 to 40.000 | + 0.002 / -0.006 |

| 40.001 to 60.000 | + 0.002 / -0.010 |

TABLE 4. HOUSING TOLERANCE (METRIC)

| BORE DIA. (mm) | BORE TOLERANCE |

|---|---|

| Over 6 to 10 | + 0.022 / -0.000 |

| Over 10 to 18 | + 0.027 / -0.000 |

| Over 18 to 30 | + 0.033 / -0.000 |

| Over 30 to 50 | + 0.039 / -0.000 |

| Over 50 to 80 | + 0.046 / -0.000 |

| Over 80 to 120 | + 0.054 / -0.000 |

| Over 120 to 180 | + 0.063 / -0.000 |

| Over 180 to 250 | + 0.072 / -0.000 |

| Over 250 to 315 | + 0.081 / -0.000 |

| Over 315 to 400 | + 0.089 / -0.000 |

| Over 400 to 500 | + 0.097 / -0.000 |

TABLE 5. TOLERANCE OF SEAL O.D (IMPERIAL))

| METAL O.D | |||

|---|---|---|---|

| BORE | INTERFERENCE | TOLERANCE | ROUNDNESS |

| ~1.000 | + 0.004 | ± 0.002 | 0.005 |

| 1.001~2.000 | + 0.004 | ± 0.002 | 0.006 |

| 2.001~3.000 | + 0.004 | ± 0.002 | 0.006 |

| 3.001~4.000 | + 0.005 | ± 0.002 | 0.007 |

| 4.001~6.000 | + 0.005 | + 0.003/-0.002 | 0.009 |

| 6.001~8.000 | + 0.006 | + 0.003/-0.002 | 0.012 |

| 8.001~10.000 | + 0.008 | + 0.004/-0.002 | 0.015 |

| 10.001~20.000 | + 0.008 | + 0.006/-0.002 | 0.2% of SEAL O.D |

| (RUBBER COVERED O.D) | |||

|---|---|---|---|

| BORE | INTERFERENCE | TOLERANCE | ROUNDNESS |

| ~1.000 | + 0.006 | ± 0.003 | 0.010 |

| 1.001~2.000 | + 0.007 | ± 0.003 | 0.010 |

| 2.001~3.000 | + 0.008 | ± 0.003 | 0.014 |

| 3.001~4.000 | + 0.010 | ± 0.004 | 0.020 |

| 4.001~6.000 | + 0.012 | ± 0.004 | 0.020 |

| 6.001~8.000 | + 0.012 | ± 0.004 | 0.025 |

| 8.001~10.000 | + 0.014 | ± 0.004 | 0.032 |

| 10.001~20.000 | + 0.016 | ± 0.005 | 0.040 |

| (RUBBER GROOVED O.D) | |||

|---|---|---|---|

| BORE | INTERFERENCE | TOLERANCE | ROUNDNESS |

| ~1.000 | 0.010 | ± 0.003 | 0.010 |

| 1.001~2.000 | 0.012 | ± 0.004 | 0.010 |

| 2.001~3.000 | 0.014 | ± 0.004 | 0.014 |

| 3.001~4.000 | 0.016 | ± 0.004 | 0.020 |

| 4.001~6.000 | 0.016 | + 0.006/-0.004 | 0.020 |

| 6.001~8.000 | 0.018 | + 0.006/-0.004 | 0.025 |

| 8.001~10.000 | 0.020 | + 0.006/-0.004 | 0.032 |

| 10.001~20.000 | 0.022 | + 0.008/-0.004 | 0.040 |

TABLE 6. TOLERANCE OF WIDTH (IMPERIAL)

| WIDTH | TOLERANCE |

|---|---|

| ALL SIZE | ± 0.015 |

TABLE 7. TOLERANCE OF SEAL O.D (METRIC)

| METAL O.D | ||

|---|---|---|

| BORE | TOLERANCE | ROUNDNESS |

| ~10.00 | + 0.20/+ 0.10 | 0.10 |

| 10.01~18.00 | + 0.20/+ 0.10 | 0.10 |

| 18.01~30.00 | + 0.20/+ 0.10 | 0.10 |

| 30.01~50.00 | + 0.20/+ 0.10 | 0.15 |

| 50.01~80.00 | + 0.23/+ 0.13 | 0.20 |

| 80.01~120.00 | + 0.25/+ 0.15 | 0.30 |

| 120.01~180.00 | + 0.28/+ 0.18 | 0.38 |

| 180.01~250.00 | + 0.30/+ 0.20 | 0.38 |

| 250.01~300.00 | + 0.30/+ 0.20 | 0.2% of SEAL O.D |

| 300.01~400.00 | + 0.35/+ 0.23 | |

| RUBBER COVERED O.D | ||

|---|---|---|

| BORE | TOLERANCE | ROUNDNESS |

| ~10.00 | + 0.30/+ 0.15 | 0.25 |

| 10.01~18.00 | + 0.30/+ 0.15 | 0.25 |

| 18.01~30.00 | + 0.30/+ 0.15 | 0.25 |

| 30.01~50.00 | + 0.30/+ 0.15 | 0.25 |

| 50.01~80.00 | + 0.35/+ 0.20 | 0.35 |

| 80.01~120.00 | + 0.35/+ 0.20 | 0.50 |

| 120.01~180.00 | + 0.45/+ 0.25 | 0.65 |

| 180.01~250.00 | + 0.45/+ 0.25 | 0.80 |

| 250.01~300.00 | + 0.45/+ 0.25 | 0.80 |

| 300.01~400.00 | + 0.55/+ 0.30 | 1.00 |

| RUBBER GROOVED O.D | ||

|---|---|---|

| BORE | TOLERANCE | ROUNDNESS |

| ~10.00 | + 0.40/+ 0.20 | 0.25 |

| 10.01~18.00 | + 0.40/+ 0.20 | 0.25 |

| 18.01~30.00 | + 0.40/+ 0.20 | 0.25 |

| 30.01~50.00 | + 0.40/+ 0.20 | 0.25 |

| 50.01~80.00 | + 0.45/+ 0.25 | 0.35 |

| 80.01~120.00 | + 0.50/+ 0.30 | 0.50 |

| 120.01~180.00 | + 0.55/+ 0.35 | 0.65 |

| 180.01~250.00 | + 0.70/+ 0.40 | 0.80 |

| 250.01~300.00 | + 0.70/+ 0.40 | 0.80 |

| 300.01~400.00 | + 0.75/+ 0.45 | 1.00 |

TABLE 8. TOLERANCE OF WIDTH (METRIC)

| WIDTH | TOLERANCE |

|---|---|

| ≤10.00 | ± 0.20 |

| OVER 10.01 | ± 0.30 |